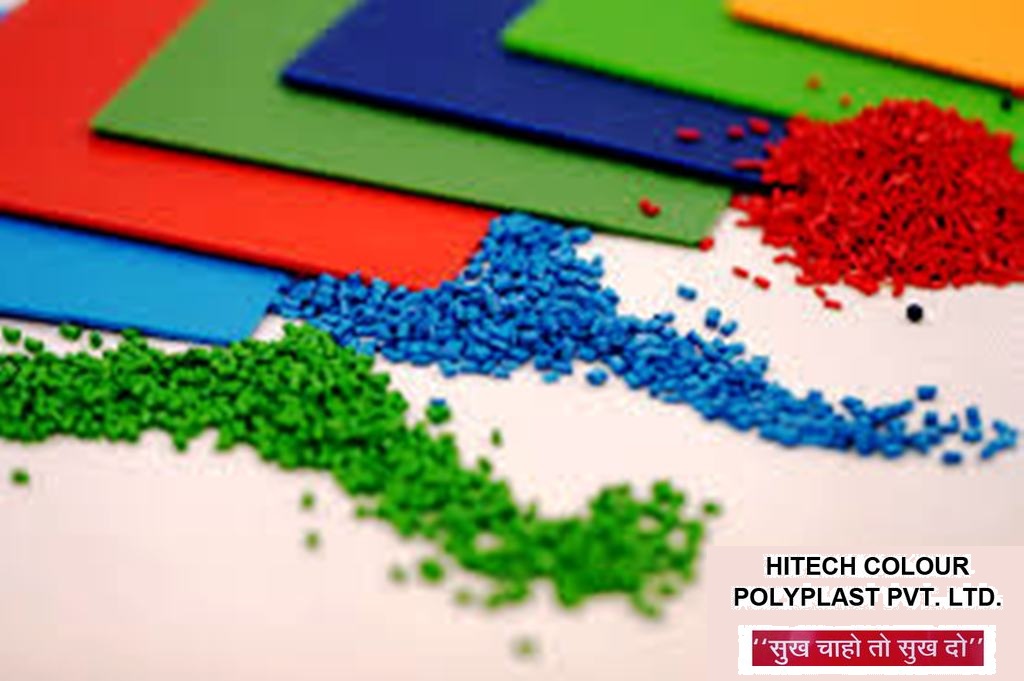

For the purpose of

coloring raw polymer economically, the use of color masterbatch is recommended

in plastic processing industry. Color masterbatch is manufactured and supplied

by Hitech Colour Polyplast Pvt. Ltd.

Color masterbatch is

used for coloring raw polymer in plastic processing industry. Hitech Colour

Polyplast Pvt. Ltd. manufactures and supplies the finest quality of color

masterbatch at competitive prices.

“Additive masterbatch

and color masterbatch are manufactured by using the latest machinery and raw

materials. White Masterbatches and Black Masterbatches are different types of

color masterbatch manufactured and supplied by us, to meet the precise needs of

plastic processing industry. Automatic processing & production facility,

Sound infrastructure set up and qualified professionals, has helped us in processing

the color & additive masterbatch in industry laid norms and regulations”

Mr. Rakesh Kumar said.

Mr. Rakesh Kumar

further said, “The color masterbatch is used for the purpose of coloring raw polymer

in various colors in the most economical manner. Standardized packaging of the

color masterbatch and additive masterbatch, ensure safe transportation at the

clients’ end. Compositional accuracy, optimum purity and enhanced shelf life,

makes the color & additive masterbatch highly appreciated among their

customers”.

Prompt delivery and

transparency in business dealings has helped Hitech Colour Polyplast Pvt. Ltd.

has established as the reputed Masterbatches

Manufacturer & Supplier.

Large color & additive masterbatch production capacity and

well-equipped warehousing unit with excellent storage capacity, has helped

Hitech Colour Polyplast Pvt. Ltd. to systematically manage the bulk assignments

of color masterbatch and additive masterbatch. Infrastructural facility is

upgraded at regular intervals of time, for the purpose of ensuring that all the

processing of color masterbatch and additive masterbatch.

Hitech Colour Polyplast

Pvt. Ltd., since its inception in the 2001, is known for processing and

supplying a qualitative assortment of Masterbatch. The masterbatch range consists of White

Masterbatches, Additive Masterbatch, Additive Master Batches, Black

Masterbatches, and Colored Masterbatches. For processing of color masterbatch

and additive masterbatch in accordance with the plastic industry laid

standards, the ultra-modern, sound and state-of-the-art processing facility are used. Qualified and

experienced engineers, technicians and support staff ensure that all the processing

of color masterbatch and additive masterbatch in the most streamlined manner. The

professionals are provided with regular training sessions through different

workshops, for upgrading them with latest happening and development in this

domain. Timely delivery, customized packaging and easy modes of payment, has

helped Hitech Colour Polyplast Pvt. Ltd. to win the trust of its clients.

Financial stability and company creditability has helped Hitech Colour

Polyplast Pvt. Ltd. to establish as one of the foremost Colour

Masterbatches Supplier in India.