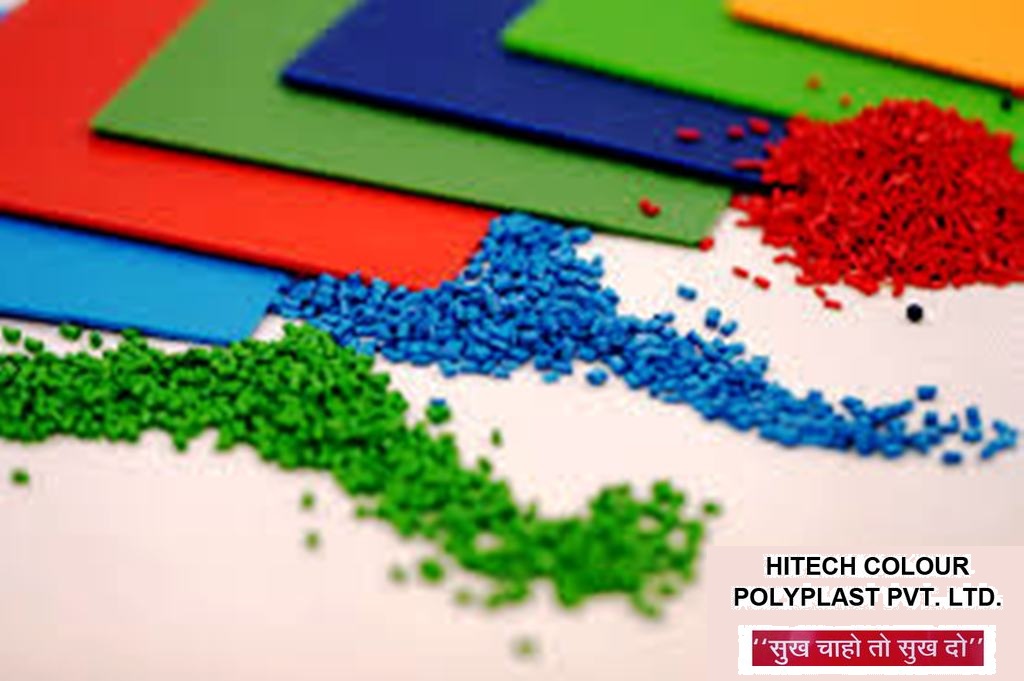

In plastic

manufacturing industry, the use of color masterbatch is recommended for the

purpose of coloring of natural polymer with optimum color dispersion and

optimum dispersion. The effective benefits of using the color masterbatch in

coloring natural or base polymer, instead of traditional coloring pigments or

dyes is effectively discussed in this blog.

In compared to the pure

pigment or dye, the use of masterbatch is appreciated as fast and convenient

method of coloring the natural polymer. The use of color masterbatch in plastic

manufacturing applications is usually associated with low stock holding as

compared with the use of pure pigments or dyes.

Besides this, the use

of high grade color masterbatch is usually associated with minimum dispersion

of color on the base or natural polymer as compared to pure pigments, dyes or

other natural ingredients. In accordance to the survey or studies conducted, it

was reported that the use of premixed composition of the color masterbatch is

known to cause no health or safety risks, as compared to other coloring source

such as power pigments, pure coloring agents or other coloring additives. In addition to this, the color masterbatch is

known to be dust-free.

In addition to this,

the color masterbatch is valued for its low cleaning cost as compared to

traditional coloring agents, pure pigments and dyes in plastic manufacturing

industries. The finished plastic products have better color compositions with

color masterbatch as compared to other traditional coloring sources, dyes or

pigments. The coloring consistency is effectively maintained and attained by

the Colour Masterbatches Manufacturer in India,

hence the use of color masterbatch effectively eliminates the “trial and error”

method of achieving the right blends of colors.

Purging or cleaning

results in huge sum of money when coloring is done by using traditional

coloring agents such as natural dyes and pigments. The reduction of the purging

or cleaning cost is one of the several benefits associated with using the best

grade of color masterbatch.

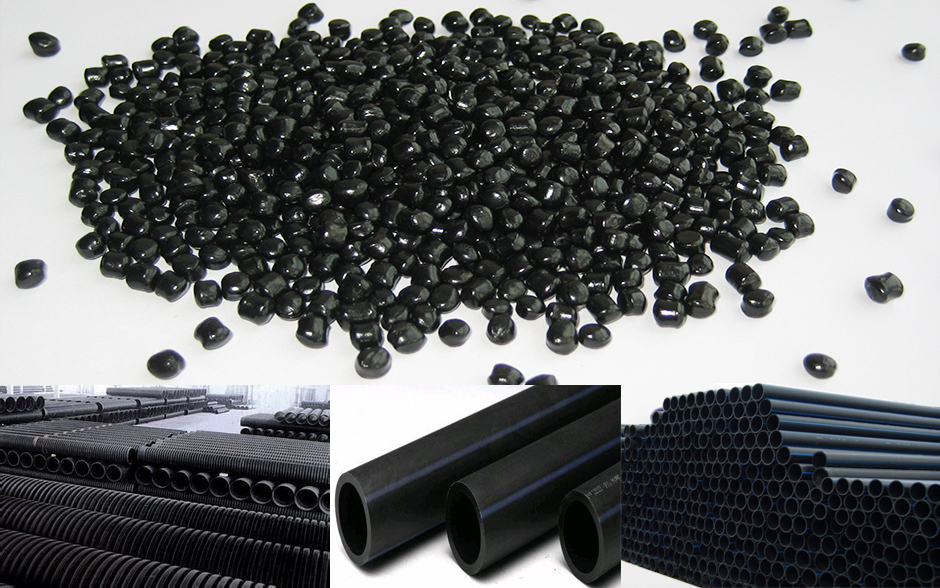

Based on the needs and

requirements, the polymer specific or universal black masterbatch can be

purchased from some of the reputed or well-known Black Masterbatches Manufacturer in India.

Being a quality focused organization;

the quality of black masterbatch is never compromised at the manufacturers’

end.

For the purpose of

manufacturing or processing the polymer-specific black masterbatch, the same

type of natural or base polymer group is used as the group being effectively

used by the processor. Whereas, in manufacturing of universal black

masterbatch, the carrier group is chosen in such as way that it can be

effectively used with a wide assortment of natural polymer.

Universal masterbatch

is easy available and is highly cost effective but are associated with severe

difficulties in processing and compatibility with natural polymers can also be

compromised in most cases. Appearance of the natural polymer is affected when

the high dose of universal black masterbatch in plastic manufacturing

applications.