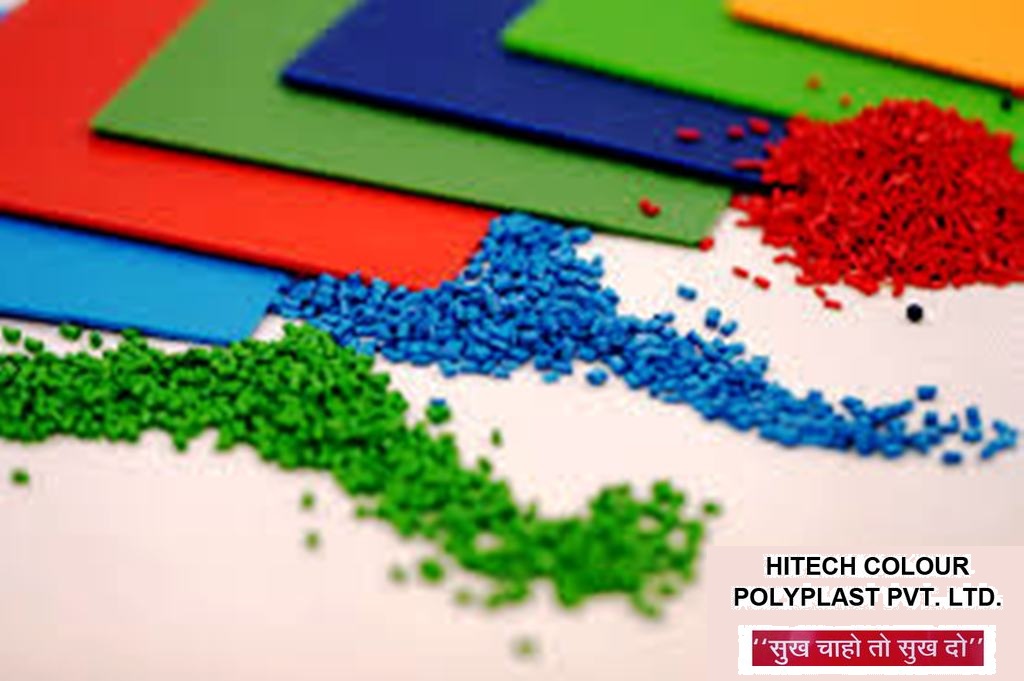

Coloring are modifying of

plastic products can be effectively done through a solid or liquid additive

that are known as “Masterbatch” can be used in plastic manufacturing processes.

Used during a heat process into a carrier resin, the color Masterbatch is used

for coloring the plastic products into music, white or multicolor.

Besides coloring the

plastic products, the masterbatch can be used for the purpose of enhancing

certain properties of the different plastic products. The additive masterbatch functions very

similar to ferroalloys, which are used for the purpose of adding different

elements to the steels.

One of the major

benefits of using masterbatch in industrial applications is that it allows the

major plastic manufacturing companies to stock less amount of high grade

synthetic polymer and effectively purchase bulk assignments of much cheaper

natural polymer. Many desired attributes can be effectively added or modified

in the natural & cheap polymers by using masterbatch, for the purpose of

suitable the manufacturing needs of plastic products. High "let-down ratios” and requirements

of large amount during manufacturing processes, make the use of additive

masterbatch for small production purposes highly uneconomical in nature.

Applications

of Different Types of Masterbatch

For the purpose of coloring

raw plastic polymer in the most economical manner, the color masterbatch is

used in heating process of the plastics manufacturing process. More expensive

and extremely low open coloring compounding materials can be alternately used

instead of color masterbatch for coloring plastic products. Besides this, many plastic manufacturing

companies make use of pure coloring pigment for the purpose of coloring plastic

products.

Some

of the Limitations/Disadvantages of Associated with Coloring Plastic Products

by Using Color Masterbatch

One of the major disadvantages

of using color masterbatch instead of pure pigment in plastic manufacturing

processes, is that the color masterbatch is often requires more space as

compared to pure pigment. The color masterbatch is often known for their

excellent extended lead times. In

accordance to the pure pigment, the color masterbatch is usually associated

with additional exposure of heat for both additive and the carrier. So the use of color masterbatch is usually

associated with coloring of plastic products that have excellent thermal

stability products. Insufficient dispersion of coloring pattern is one of the

major disadvantages associated with color masterbatch, as color masterbatch are

rendered in premixed composition. Colorant clumping is another disadvantage

associated with coloring of plastic through color masterbatch. The

concentration of color masterbatch is much higher than traditional coloring

pigment.

Why

to Buy Color Masterbatches from Reliable Manufacturers and Suppliers?

Excellent storage

facility and rich vendors’ base has helped Colour Masterbatches Supplier in India

to precisely meeting the bulk assignments of colour masterbatch. Besides using

latest machinery for manufacturing the color masterbatch in accordance to the

industry laid norms, the Colour Masterbatches Manufacturer in India

follows total quality assurance procedures for ensuring that the quality of the

Masterbatches is never compromised.

No comments:

Post a Comment