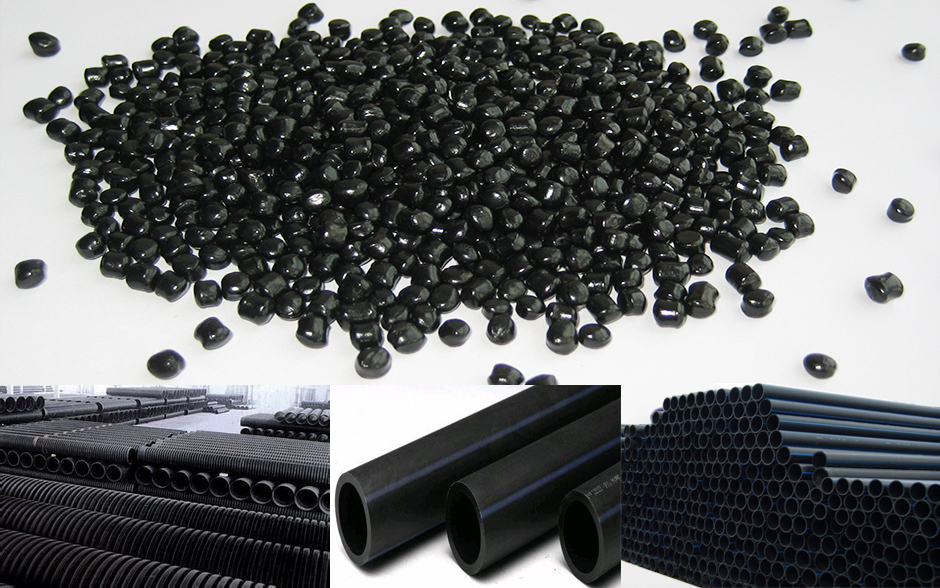

Manufactured by using

latest machinery, the black masterbatch can be directly used in the machines’

screw, for coloring plastic products in black as a

free-flowing solid. Besides this, the masterbatch can also be used directly in

case of a liquid masterbatch by systematically executed peristaltic pump.

Extremely accurate dosing and effective & quick change of the black color

between the plastics manufacturing machinery runs, are often associated with

the liquid masterbatch, which is systematically processed by reputed machinery.

Besides this, the

masterbatch can be used traditionally with the premixed granules with the host

polymer, for the purpose of coloring the plastic products into black colors.

One of the complications associated with premixing the masterbatch with the

host, is that the separation of the base material and masterbatch in the

machine’s hopper can be highly uneconomical in nature.

In plastic

manufacturing or processing industry, the use of color masterbatch is

associated with additional exposure of heat. The heat history to both the

carrier and the additive can be associated color masterbatch while coloring the

plastic products. Hence the use of for marginally thermally stable pigments

over the traditional color masterbatch is recommended in various industrial

plastic coloring applications. One of the primary advantages of using solid

Masterbatches is that its compact nature of grains systematically eliminates

different problems associated with dusts which are one of the major problems

associated fine-grained solid additives. Higher accuracy in dosing is often

associated with relatively dilute nature of colored or additives Masterbatches.

Universal carrier in

form of wax is often used as the effective carrier material of the masterbatch

on specific polymer. With ability to buy cheaper natural polymer in bulk and

stocking of synthetic polymer, has helped the use of additive or color

masterbatch in plastic manufacturing companies is highly demanded.

As per the recent

studies conducted over the use of disadvantages of use of color masterbatch in

plastic manufacturing processes, it was reported that the use of color additives are associated

with insufficient dispersion of color as the color Masterbatches are rendered by premixed compositions. In addition

to this, the use of masterbatch is also associated with large storage space and

their lead times time. Fairly high concentrations with extremely “let-down

ratios” are some of disadvantages of associated with use of color masterbatch.

If the plastic products

are colored in black color and the use of pure pigment is not economical, hence

the plastic manufacturing companies can make use of black masterbatch

manufactured by reputed Black Masterbatches Manufacturer in India.

Ideal for most of the

plastics manufacturing processes but the masterbatch even manufactured by the

best Masterbatches Manufacturer & Supplier

cannot be used in rotational molding. In addition to this, the masterbatch even

cannot be used with liquid resin system and plastic manufacturing processes

that involves Plastisol.

No comments:

Post a Comment