The

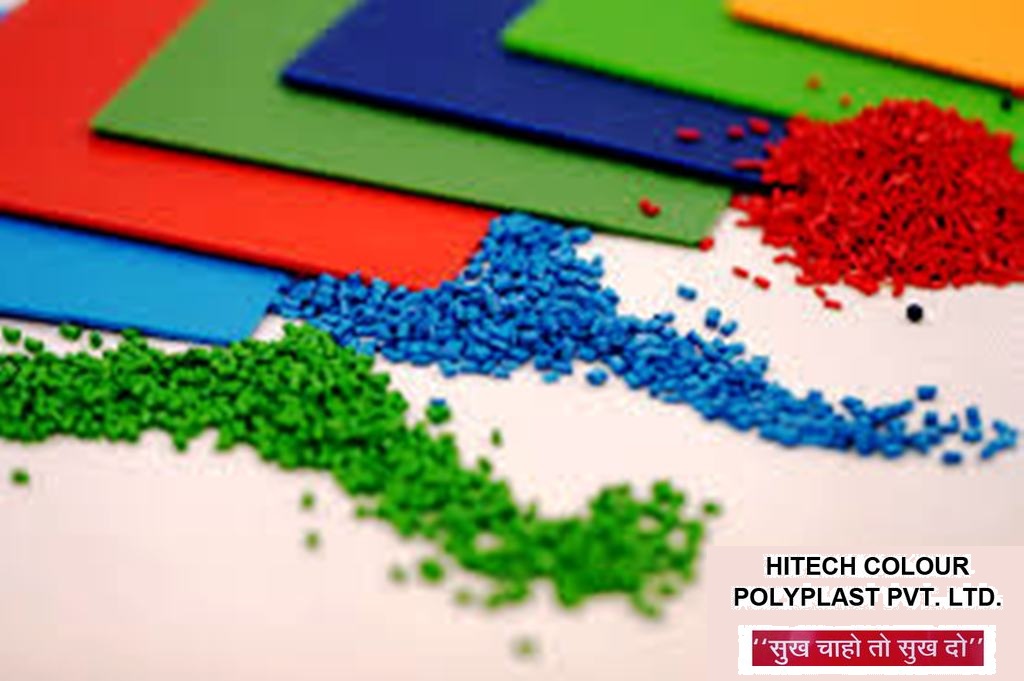

masterbatches are used in plastic industry. They are used to give color to raw

polymer during plastic making process. They are concentrated pigments or

additives which are enclosed in carrier resin during heating process, which is

then cooled and cut into granules. With the use of masterbatches, a factory can

keep fewer grade of polymer and in addition they can cheaper polymer in bulk

quantity. The amount of additive in the masterbatches is 40-65 % but it can go

up to 80 % in some cases.

Use of

masterbatches—

They

are used to add color to plastic products during plastic manufacturing. They have

wide range use in packing, agriculture, automotive and consumers industry and

also are used to make thin plastic pressure films, fibers, bottles and pipes.

Lamination, coating, high temperature and high speed intrusion are other uses

of various types of masterbatches.

Type of

masterbatches—

White

masterbatche,

--this masterbatch is made with additives and formulation recipe. It is

available with loading of Rutile grade titanium dioxide up to 70 %

Black

masterbatches,

-- this category contains specially selected black carbons to impart the

qualities of UV protection and food contact approval to plastic goods.

Addictive

masterbatches,--this

category includes anti block, UV protection, anti slip, anti fog and

antioxidants properties which are suitable for thermoplastic industry.

Color

masterbatches –

Color

masterbatches contain quality pigment and are made with superior mixing

process.

They

have different shades such as transparent, and give metallic and pearlite

special effects. The carriers which are used in their making are ABS, PE, HIPS,

PC and NYLON.

Uses of color

masterbatches –

Color

masterbatches are used in making yarn for carpets. They are also used in

molding, Rota, blow and injection applications.

Benefits of

color masterbatches --

The

appearance and performance of resin is molded to suite the exact

specifications. It provides heat resistance, keeps end product light without

migration properties and gives strength and color stability.

Among

large number of Masterbatches Manufacturer& Supplier of, few are

equipped with state of the art facilities to manufacture quality masterbatches

for clients based on their specifications and needs. For quality Color Masterbatches Suppliers in India one can

contact the company which has time bound delivery with transparent business

practice and employs highly trained professionals in advanced units.

No comments:

Post a Comment